Product Techs

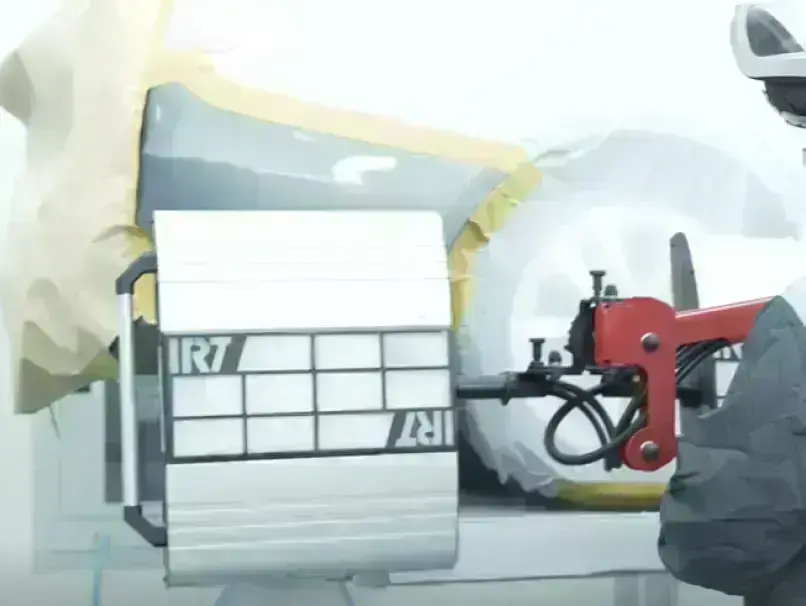

UV technologies

UV-A repairs from R-M at the speed of light

Up to 25% faster process times when compared to oven and infrared drying

This faster process leads to 40% more jobs

On average, body shops use up to 50% less energy on each job with UV-A technology

eSense

eSense: good for cars and for the environment

The new type of repair – with R-M’s eSense products

Thanks to e’Sense, we saved 3.363t CO2

*BASF product carbon footprints are calculated following general standards for life cycle assessment and product carbon footprints. The product carbon footprints are assessed cradle to gate, i.e. without CO2 emissions caused during product application and end-of-life treatment. Our product carbon footprint data is based on assumptions and approximations valid at the time of data collection. For more information, please visit https://www.basf.com/global/en/who-we-are/sustainability/we-drive-susta… eSense products contribute to reducing the use of fossil resources and reducing the CO2 emissions via the biomass balance approach. In BASF’s biomass balance approach, renewable raw materials like bio-based naphtha and biomethane from organic waste are used as raw materials when manufacturing primary chemical products and are fed into the production Verbund. The proportion of bio-based raw materials is then arithmetically assigned to certain sales products according to a certified method. This attribution model is comparable with the principle of green electricity. For our biomass balance products, 100% of the feedstock required for these products (chemical product only / excluding packaging material) have been replaced by renewable resources. All our eSense products are independently certified according to the RedCert² standard. (BASF certification number REDcert²-929-35346515). For more information, please visit https://www.redcert.eu. When reference is made to CO2 savings per traveled kilometer, a standard CO2 emission of 95 grams per travelled car kilometer is assumed. Here you can find more information about BASF’s biomass balance approach: https://www.basf.com/en/bmb

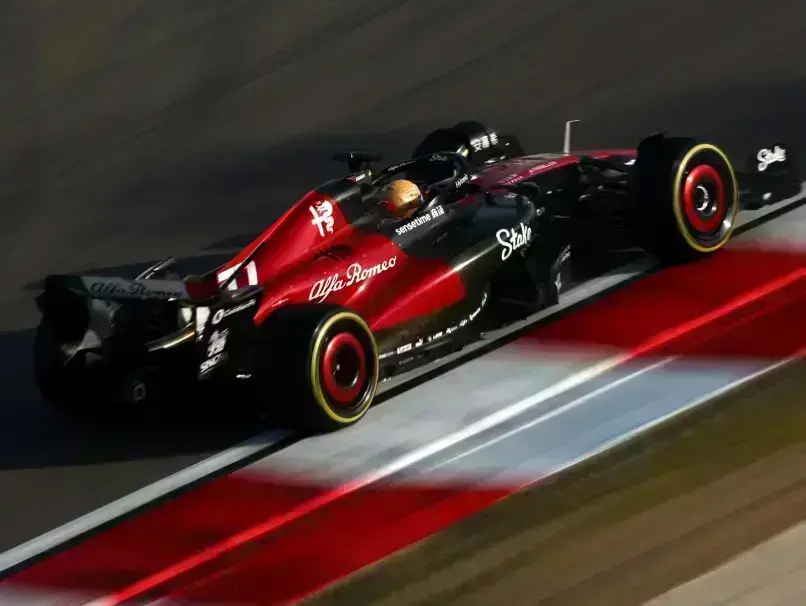

Team up with R-M and accelerate your business success

Connect with your local R-M dealer now